Condenser is very important equipment that is used in many major industries where you need huge temperature differences. A condenser is a unit used in the systems where large amount of heat transfers is involved and is used for changing the state of a substance from gaseous to liquid form. In the process of condensation, an amount of latent heat is released, which is absorbed by the coolant of the condenser. Basically, condensers are used widely in HVAC and refrigeration to get rid of the heat extracted from various places. The major industries that use condensers extensively include ice factories, food storage, cold storage, air conditioning, etc.

The working of a condenser or a heat pump is just like an air conditioner but has some minute differences. The air-conditioner can be used for only cooling purposes, but a heat pump or condenser can be used for both heating and cooling purposes.

One main concern for better operation of a condenser is to maintain an optimum level of re pressure in the condenser to maintain best working levels. The working of a condenser is based on a simple principle that when a fluid is compressed to a great extent, the temperature of the fluid is also increased greatly. If you lower down the temperature of that compressed fluid and then decompress it, the temperature of decompressed fluid would drop to a great degree. This vast temperature drop can be used for cooling purpose at various points.

One main concern for better operation of a condenser is to maintain an optimum level of re pressure in the condenser to maintain best working levels. The working of a condenser is based on a simple principle that when a fluid is compressed to a great extent, the temperature of the fluid is also increased greatly. If you lower down the temperature of that compressed fluid and then decompress it, the temperature of decompressed fluid would drop to a great degree. This vast temperature drop can be used for cooling purpose at various points.

The tubes of a condenser are very important for the smooth and efficient working of the condenser. The tubes contain the working fluid of the condenser, which is usually a refrigerant. If the tubes of the condenser are in an optimum state, your condenser would be able to provide you the best efficiency, but if they are not in a good working condition or have any defect, it will lower the efficiency of the condenser and also leads to economic losses.

The tubes of a condenser are very tender and delicate; hence they can be damaged very easily. The various factors that can be reason for the damage of the condenser tubes can be corrosion, chemical contact or mechanical impacts. When the condenser is used for a long time, the tubes also get clogged due to some dirt, which is introduced to the tubes. There can also be leakage in some parts of the condenser tubes, which can lead to leakage. If there are leakages in the tubes, the refrigerant would leak from the tubes and condenser would not be able to work properly.

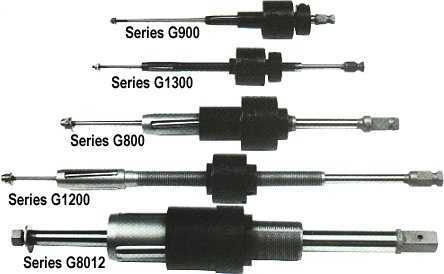

In order to keep your condenser at optimum health and protect it from any type of major damage, you must take good care of it and carry out regular maintenance of your condenser. For proper maintenance, you will need several sophisticated tools such as condenser tube expanders, tube cleaners, etc, which will keep your condenser in an optimum and healthy state.