To offer heat and cooling effect for changing one state to another, condensers, boilers, heat exchangers, and other special machines are employed. To give power to the machinery, they are utilized in different factories, industries, and manufacturing units also. With the utilization of tube sheets fitted with boilers, one state of matter is converted into the other state. To mold and to give shape to the diameters of the tube, they require special tube expansion systems that assist in adjusting the diameter of the tube sheets.

Various special kinds of tools and parts are fitted with boiler tube expanders which assists in less effort required in shaping and facing tube sheets inside boilers. The procedure of filling the tubes and enhancing the diameter for moreefficiency and betteroperations helps in simplifying the whole procedure.

The concerned companies are involved in the production of the expanders that are made available in several forms, characteristics, and dimensions. These expanders are available on the offline shops and on the online websites of the companies working in this field at much economical prices. The expanders are mainly utilized in the manufacturing units that are directly involved in utilizing the boiler to power up the machinery and manufacturing head exchangers and condensers.

There are basically three kinds of tube expansion systems that are as follows:

- Electric tube expansion system

- Pneumatic rolling motors

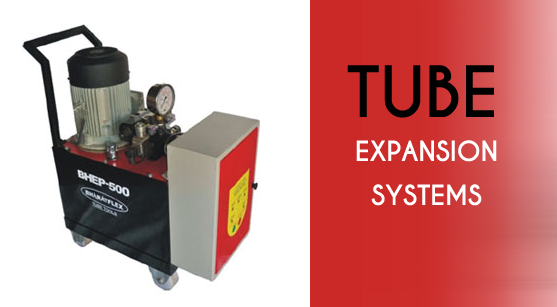

- Hydraulic tube expansion system

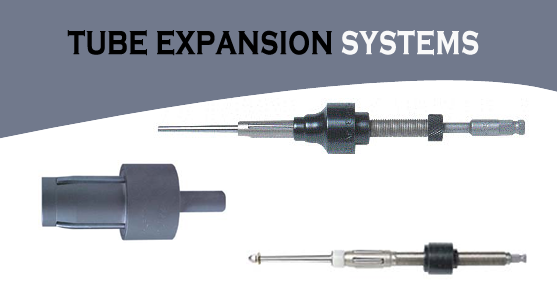

All the equipmentare well-fitted with the essential parts such as end faces, pilots of various thickness & diameters, aligned rollers, and mandrel. All the mentioned parts operate in a manner to offer the optimal outcomeconcerned with the required work i.e. expanding and facing tube sheets. These are composed of titanium and best in class protective layers are coated over it so that it can last for maximum time and are lasting in nature. These components are heat proof and give frictionless expanding capabilities without causing any kind of damage to the condenser tubes.

In addition, these can also be utilized without being afraid of any type of accident or damage triggered due to an explosion. These parts are used in radiators, condensers, and in several machines that utilize tube and steel technology. Additionally, the latest kinds of expanders are fitted with the required parts which assist in creating the molding process more precise. The head frame on the expanders assists in offering more support and durability to the machine. The utilization of titanium materials and stronger steel helps in making the condenser expanders the best tools for performing the eeded activities with more effectiveness and efficiency.

Powermaster is a company that provides such kind of gears and tools for tube expanding and it also ensures that all the equipments are of the highest quality and remain operational for a longer period of time. They provide various kinds of services like hot bolting, re-tubing, in-situ machining, controlled bolting, etc. The products of Powermaster are used in more than 120 countries which prove that provides the best kind of services to their clients.