With the increasing trend towards better quality of products, customers are now ready to pay anything for better quality products. This has also encouraged industries to use the best available technologies and machines to produce only the best quality of products. This is the only way for industries to beat the fierce competition in the markets. There is a wide variety of equipment and machines that are used in industries for production of better quality products. One such equipment is boiler. The boiler is a type of giant equipment that is used for production of very high amount of heat and pressurized steam. This heat and steam are further used for a variety of processes and purposes such as heating, boiling, sterilization and many more.

The boiler is such a huge and giant machine that it needs a high level of care and maintenance to stay safe and keep running for a long time. If the companies ignore the care and maintenance of ether boilers, they not might lose a lot of money in a very little time, but it can also be very dangerous for the people working around the boiler.

When it comes to boiler maintenance, there is a plethora of tools and equipments that one needs to take good care of a boiler. Here are some of those.

Boiler tube cleaners

Boiler tube cleaners are regularly used for cleaning the tubes of a boiler. These systems are used for removal of sludge, scale and other foreign particles from the inner surface of the tube so that they could perform with full efficiency. There are several different types of tube cleaning systems available in the markets such as electrical, pneumatic and hydraulic tube cleaners. There are also portable tube cleaners available that are very easy to use and handy to carry.

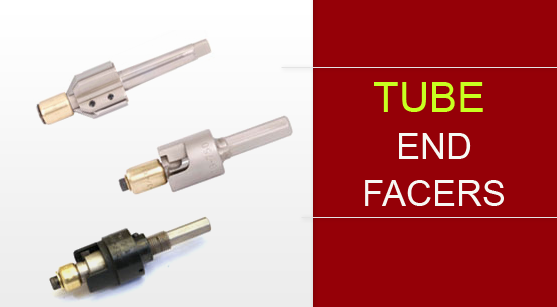

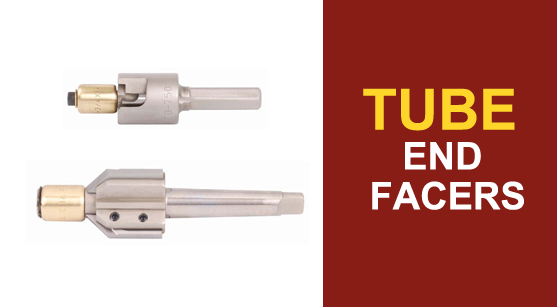

Tube End Facers

When a new tube is installed in a boiler, many times the tubes become shorter for the length of the boiler. In that case, two tubes are joined together to obtain a desired length. These tubes are joined through welding process. For a stronger joint, the ends of the tubes must be perfectly flat and free from any holes or grooves. The tube end facers are the ideal tools to give the tubes a perfectly flat face so that and efficient and long lasting weld could be created at the joint of the tubes.

Tube expanders

Tube expanders are used for increasing the diameter of the tubes when they are smaller in size as compared to the cavity in the tubes sheet. The tube expanders are best for increasing the size of the tubes to a significant level without causing any damage to the tube surface and without taking much time.

Along with these, there are flaring tools, tube pullout tools, tube drift and many others that help in keeping the boilers efficient for a long time.