There are many occasions wherein the need of a tube expander is required by the manufactures. In fact, tube expander is one of the inevitable tools at their disposal which makes their work easier and faster. There is plethora of tube expander manufacturer in the market from whom the desired tube expander tool can be purchased. But before plunging to buy the tool, it is imperative to understand the basics of the tools and its functionalities. This will help to get the apt tool as per requirement. So here is a basic touch up about the tube expander tools:

What is a tube expander?

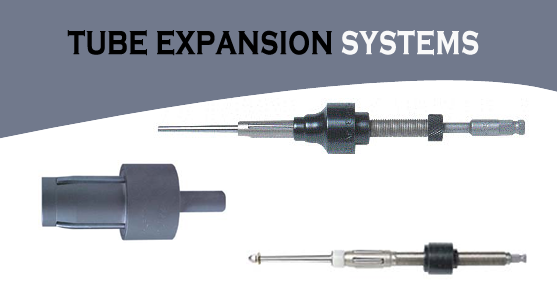

As the name suggests, a tube expander is a tool, which is used for the expansion of the tubes into sheet like forms. This is ideally used in manufacturing firms in the boiling and condensing work. Tube expanders are rolling tube type tools that make this process easier and faster.

Components of a tube expander

A tube expander generally consists of four main parts. Depending on the way that they are joined together, two different variation of the tube expander can be designed. This depends entirely on its construction, which is generally referred to as the CB and BK Construction. Here are the main components of the tube expander

- Roller– This is one of the most important parts of the tube expander tool. The roller consists of R- shaped smooth chamfer, which is tapered in shape. Its main function is to apply a rolling pressure on the insides, which is perfectly done by the tapered end. Further, tool is so designed that it helps to get a perfect spherical shape, which is the need. The roller action is the first action that happens on the tube, and the entire construction is done strategically to facilitate the rolling process without causing any extra stress or causing sharp edges.

- Mandrel– Mandrel supports the roller to facilitate the rolling process. Actually both the roller and the mandrel are required for the rolling action and hence, both their structuring in tapered form is necessary. Since, they aid in the rolling process, these parts need to be abrasion resistant, which is ensured by their steel type (undergoes special heat and grinding treatment to achieve this). They use the principle of contact friction to achieve the rotation process.

- Frame– The frame provides a sort of support to the roller and the mandrel creating a screw feed like mechanism by providing the essential feed angle. This mechanism is the core setting of the automatic expansion of the tube expander.

- Bearing Collar– A bearing collar basically helps to reduce the thrust and prevent any sort of damage to the tube sheet during the expansion process. Usually, it is adjustable and can be flexed to the desired length.

Now that you know about the core components of the tube expander, it will become a little bit easier to use it. Tube expander is equally effective for parallel tube expansion as well as flare tube expansion. So, use it as per d