The tubes are used in industries to a huge extent. In fact, it is the best medium to move the chemicals and vapour as well as some hazardous gases that cannot be moved by human efforts otherwise. The tubes have proven as a vital part of the production process due to its excellent utility. One can find different types of tubes such as copper, aluminium, steel and iron that are used in various processes. For the industries, all such tubes prove much helpful, and hence they need to be maintained well.

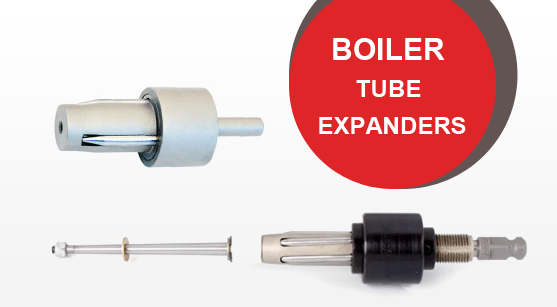

To move the gases and vapour it is much important that there is no leakage in any part of the tube and even at the area of joint. Therefore the experts in the industry suggest the fixing of tubes in a way that there is no such joint is required. Usually, the tubes used in the industries are of the same size and hence one cannot fix both the ends of the tubes together. In such scenario, the user needs to expand the end of one tube so that the end of other tube can be fixed easily. This can be done with the help of tube expanders easily. It is a device designed in a way that the pressure of the same to the tube can gradually lead to the expansion of the tube end.

The device:

The use of the tubes in the boiler area is common where the material to and from the boiler is carried out. The boiler tube expander can help the user to expand these tubes in the desired way so that the decided task of moving the chemicals is carried out easily. The expansion of the tubes can be done in a limited period with the help of such quality devices.

Get the device:

Getting the device is not a tough task nowadays as the buyer can go for the offline purchase or from an online store. The offline shopping is an easy way of getting the device as in this method the buyer needs to go to the shop, check the device and pay the amount if he likes it and features can match the need of the device. The buyer here can pay the amount in cash and in case of any query get the solution for the same from the seller. It proves as the best option if one wants to have an urgent use. The buyer here may not get the device with the latest features and that too with a discount.

For a buyer who has time and not the urgency of the device, the online store can be the best option. Here the buyer can check the devices with different features and that too at a discounted price before buying any of the devices. The buyer can use digital channels to pay the amount to the store. The store sends the device by courier, and it can be availed to the buyer in a few days at his doorstep.