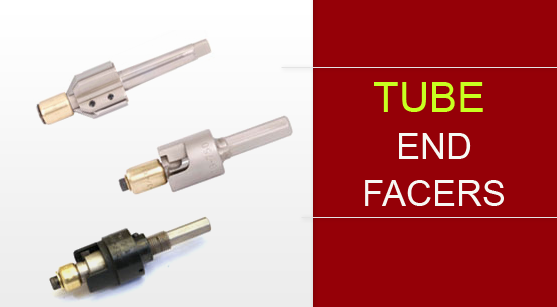

One of the most extensively used technologies in majority of the firms is the piping. Firms ranging from nuclear power plants to food industries require piping to carry out their functions. Proper installation and right maintenance of the tubes can significantly improve the efficiency of the firm. One has to be cautious while dealing with these tubes as they are highly prone to be damaged by the scales and sludges. If neglected, these materials act as heat insulators and reduce the efficiency of the firm drastically. Clean them regularly to free them from debris. Often, when the tubes get damaged too much, you may have to replace them with the newer ones. During this installation process, tube end facers can be a lot handy. Check out more about them.

What Exactly Is Facing…?

Facing operation is carried out to bring out smooth surfaces at the ends of bars and tubes. Often, this process is also employed to cut the ends of the bars or tubes to bring out dimensional accuracy. The applications of this tool are…

Before expanding the tubes, the tube end facers are employed to make sure that the projections of the tube ends are uniform.

Before expanding the tubes, the tube end facers are employed to make sure that the projections of the tube ends are uniform.

- In boilers, tube ends are made to have uniform projections before they are rolled.

- The cut or rolled tubes are de burred with this tool.

They are widely employed in power plants, oil and gas refineries, sugar factories and a few other food industries.

Features:

The much anticipated features of tube end facers are listed below:

- Minute feed adjustment can result in smooth and precise machining. The material removal can be controlled with ease.

- Coating a tool bit with materials like titanium can prolong its lifetime. This also makes the tool to withstand the extreme working conditions.

- The tool is expected to have improved safety features like safety shields and guards.

- Interchangeable pilots can increase the versatility of its applications.

- Bevel cutting can also be performed, if a holder is provided.

Cutting holders and inserts can be a lot handy while dealing with tube end facers. Lithium ion rechargeable batteries are used with these devices.

Precautions:

- The operator must be equipped with all the safety devices like goggles, gloves, etc.

- Make sure that all the electrical and hydraulic connections are secured tightly and safely.

- Lubricate the moving parts with the specified lubricants so as to reduce wear on the materials.

- Preserve the tools safely by protecting them against external environmental factors like moisture, heat etc.

Get Online:

Sometimes, it might be real difficult to get the one which best fits your requirement. However, when you choose to select from online stores, you can have the flexibility of choosing from a wide range of products. In such a case, the chances of getting your requirements fulfilled are quite high. Check out for the product descriptions and shipping prices while purchasing the products.