Perfect bonds can be ensured by applying the techniques of tube expansion. These methods are widely used in various fields. In this article, we detail you all about boiler tube expanders. Prior to the tube expansion, the operator has to make sure that the expander is clean. Any traces of dirt or grease can result in imperfect bonds.

Tips To Ensure Perfect Expansion:

- Tubes can be installed with ease when the tube holes are pre rolled. This process can also rectify the imperfections in the hole.

- In case of dealing with smaller boilers, the tubes should be cut into smaller lengths before inserting into the holes.

- One end of the tube is to be pinned whereas the other end is rolled. A trimming tool can be employed in removing the excess tube projection.

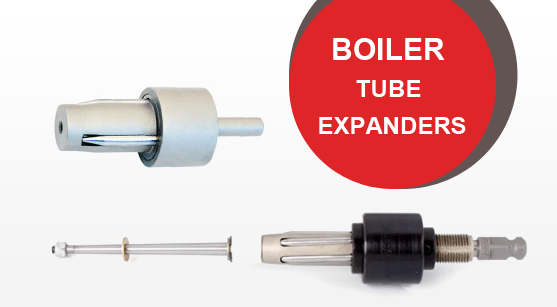

The components and structure of tube expander may vary with the application and type of equipment. A few basic components are detailed below:

- Rollers: A smooth finish is ensured on the ends of the roller which eliminates stress concentration that takes place after expanding the tube. These devices help in retaining a perfectly circular shape of the inner surface of the tubes after expansion.

- Mandrel: They aid in rotation of the rollers and are designed to have a tapered shape. Depending upon the application, suitable materials are chosen in their manufacture so as to withstand the operating friction and pressure.

- Frame: Multiple rollers can be held at equal intervals in a frame. Roller drop can be prevented with this device.

- Bearing collar: It is aimed at protecting tube ends and tube sheets. This is facilitated by reducing thrust developed in the process of tube expansion to safer levels. This device can be positioned in the forward or backward direction by which the effective length of roller is adjusted.

Types:

To meet the rapidly increasing application, newer designs are entering the market with time. The types of boiler expanders vary with respect to several factors like applications, manufacturers etc.

Straight roll boiler expanders: As the name suggests, they are used in straight roll expansions. A practical example of its application is, re rolling leaking joints.

Flare roll boiler expanders: They are designed to be used specifically in fire tube boilers. In a single operation, rolling and flaring operations can be done.

Single roll beading tube expanders: Simultaneous expansion and formation of beads, each at two opposite extreme ends can be achieved by these devices.

Mandrels: Drum, short and reverse mandrels are the popular types. If the operator can access tube sheet with ease, then the drum mandrels have to be preferred. They are replaced by short mandrels in tight working conditions. If the tubes have to be expanded from the opposite direction, then reverse mandrels are employed.

Use of lubricants and coolants during tube expansion are highly recommended. The lubricant used, has to be highly viscous (a paste style).